Osteosynthesis is a surgical method used to stabilise broken or displaced bones through internal fixation. Traditionally, standardised plates, screws and pins were used to hold bone fragments in place. Patient-specific osteosynthesis uses custom-made implants precisely designed to fit the patient’s bone structure, offering a significant advantage in terms of accuracy.

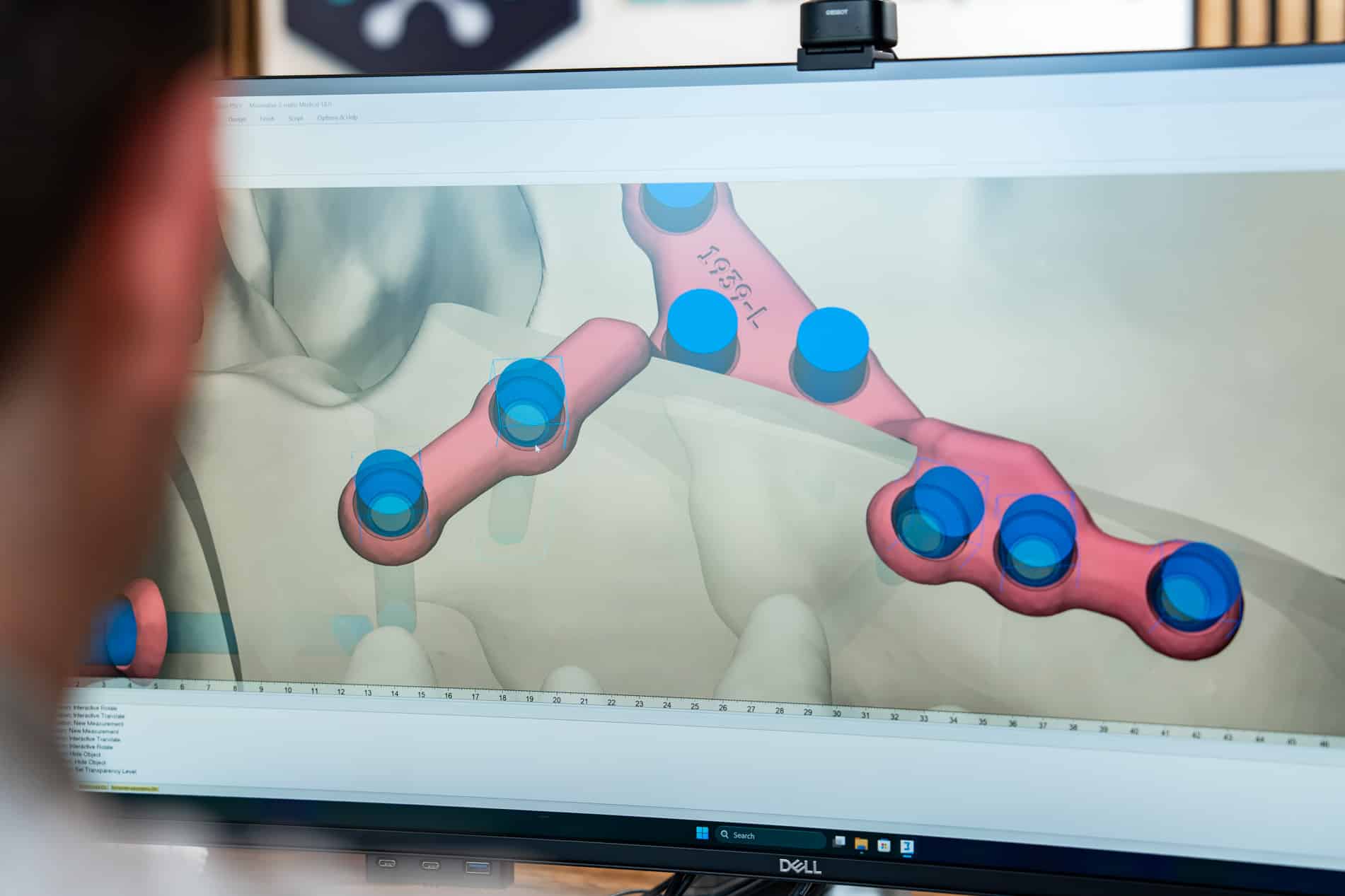

The process begins with comprehensive pre-operative planning, using 3D imaging techniques to map the patient’s precise anatomy. Using these images, virtual models of the damaged bone or bone to be treated are created. Based on these models, a patient-specific implant or fixation device is designed to perfectly fit the shape and contours of the patient’s bone.

Thanks to advanced Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) software, every aspect of the implant or fixation plates can be precisely personalised, from the size and thickness to the placement of the screws and drill holes. This leads to a better fit, less tissue irritation and faster and more stable bone healing.

The tailored approach to osteosynthesis offers numerous advantages over traditional methods:

The materials used for patient-specific osteosynthesis are carefully selected to be both biocompatible and durable. We use titanium. Titanium is often used in osteosynthesis because of its strength, low weight and high biocompatibility. It is corrosion-resistant and integrates well with bone, making it ideal for long-term implants.

Laden Sie unseren Leitfaden zur Osteosynthese herunter. For a hard copy, please email info@3dvsp.com.

ISO 13485 is the global standard for quality management in medical device manufacturing.